โทร :

+86 18681515767

โทร :

+86 18681515767

อีเมล์ :

marketing@jtspeedwork.com

อีเมล์ :

marketing@jtspeedwork.com

โทร :

+86 18681515767

โทร :

+86 18681515767

อีเมล์ :

marketing@jtspeedwork.com

อีเมล์ :

marketing@jtspeedwork.com

The Infrastructure Behind Space Factories: RFID and Full-Lifecycle Manufacturing Control

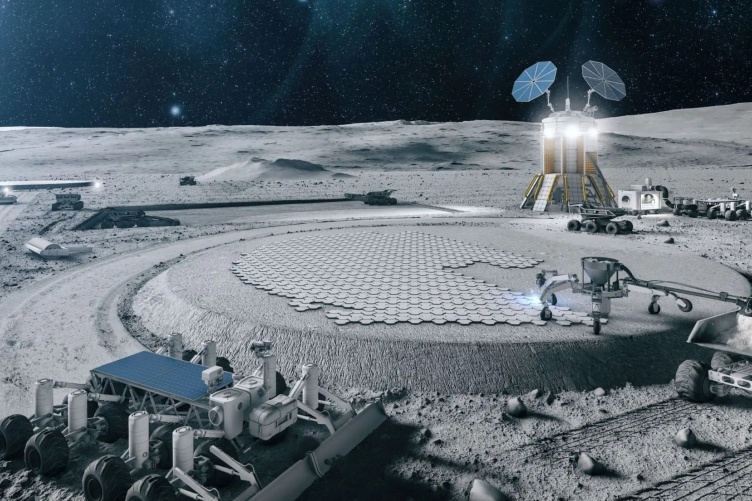

As commercial spaceflight continues to advance, humanity is transitioning from merely entering space to sustaining production beyond Earth. Concepts such as in-orbit maintenance, on-orbit assembly, microgravity manufacturing, and space factories are gradually moving from theoretical exploration to practical engineering. In this process, manufacturing in space is no longer just a technological challenge, but also a management challenge. How to accurately manage materials, equipment, and production processes in a highly complex, remote, and irreversible environment has become a critical factor in determining whether space factories can operate reliably over the long term.

Compared with terrestrial factories, space manufacturing faces far more stringent constraints. Vacuum conditions, intense radiation, extreme temperature fluctuations, and microgravity environments make traditional management approaches based on manual operations and visual inspection difficult to apply. At the same time, any assembly error or process deviation may lead to irreversible consequences, as in-orbit repair or rework involves extremely high costs and, in some cases, is simply not feasible. This reality requires space factories to be designed from the outset with a high degree of automation, consistency, and full-process traceability.

Against this backdrop, RFID technology has emerged as a strong candidate for the digital foundation of space factories. RFID is not a new technology, but its non-contact identification, unique item-level identity, and batch reading capabilities make it particularly well suited to enclosed, remote environments dominated by robotic operations. In space factory scenarios, RFID systems built around UHF RFID antenna architectures can maintain reliable performance even in metal-rich, confined modules, enabling stable identification without direct line-of-sight.

Throughout the entire lifecycle of space manufacturing, the role of RFID begins on the ground. After components are manufactured, RFID tags designed to withstand extreme temperatures and radiation are embedded or attached to critical parts, recording key information such as material origin, process parameters, inspection results, and quality status. During system integration and launch preparation, RFID systems can automatically verify loading lists through industrial RFID reader platforms, reducing the risk of missing, incorrect, or mismatched components and providing an additional layer of assurance for launch missions.

During the launch and orbital insertion phases, RFID continues to play a subtle yet critical role. Within rocket fairings and spacecraft modules, distributed reader networks—often based on long range RFID reader module designs—can be used to confirm the integrity and configuration of equipment throughout transportation and launch. This continuity of information helps eliminate traditional “data discontinuities” that often occur after launch, laying a reliable foundation for subsequent in-orbit deployment and activation.

Once equipment enters space stations or space factory modules, RFID becomes a core tool for in-orbit inventory and resource management. Tools, spare parts, and raw materials no longer rely on human memory or manual records, but are instead tracked through real-time identification and inventory visibility. This reduces the workload of astronauts while providing essential data support for robotic retrieval, placement, and scheduling, significantly improving operational efficiency in orbit.

During in-orbit assembly and manufacturing, RFID is further integrated with robotic systems and mission control platforms. Before assembly, the system can automatically verify component models, versions, and assembly sequences to ensure the correct parts are used. During assembly, each operational step can be recorded and traced. After completion, a comprehensive manufacturing and assembly history is preserved, providing a reliable reference for future operations and maintenance. This mechanism greatly reduces the probability of human error and improves first-pass success rates in space manufacturing.

Throughout the operational phase of equipment, RFID also plays a key role in maintenance and lifecycle management. By recording usage frequency, maintenance history, and replacement cycles, the system supports lifespan assessment and risk prediction for critical components, enabling data-driven decisions for in-orbit servicing and mission planning. Even after equipment is retired or replaced, the accumulated lifecycle data remains valuable for optimizing the design and execution of future missions.

As digital twin technologies, artificial intelligence, and automated control systems continue to evolve, RFID is shifting from a simple identification tool to a primary data gateway between the physical and digital worlds. It anchors virtual models to real physical objects, enabling space factories to be continuously sensed, analyzed, and optimized within digital environments. Without a stable and reliable foundational identification and tracking layer, higher-level intelligent systems cannot truly function as intended.

From a broader perspective, space factories represent experimental platforms for intelligent manufacturing under extreme conditions. RFID-enabled full-process traceability models validated in space environments are likely to be applied in other domains, such as deep-sea manufacturing, nuclear industries, high-risk operations, and long-duration unmanned facilities. In this sense, space manufacturing not only extends humanity’s operational frontier but also reshapes the boundaries of industrial management.

As manufacturing activities move beyond Earth, traditional management methods reliant on manual intervention and experience become increasingly insufficient. RFID may not be a high-profile technology, but its stability, reliability, and scalability make it an essential digital foundation for space factory operations. In future space manufacturing systems, every component, every operation, and every decision will be accompanied by a clear and traceable digital footprint—and RFID will serve as the invisible thread connecting the physical universe to the digital world.

หมวดหมู่

บล็อกใหม่

ลิขสิทธิ์ © 2026 Shenzhen Jietong Technology Co.,Ltd. สงวนลิขสิทธิ์.

รองรับเครือข่าย ipv6